Real-time control and working condition conversion of the test system by computer, automatic completion of impact test control of steering gear, real-time acquisition of test parameters, accurate calculation of various performance indicators, etc., and recording of experimental data in the form of graphs, curves, etc. Finally, the display and printing of experimental data is realized.

Main performance:

● Pendulum impact mass: 67Kg

● Swing arm length: 1655mm

● Maximum lifting angle of pendulum: 50°

● Drop hammer impact quality: 50Kg

● Maximum impact height of the drop hammer: 1000mm

● Impact detection range: 100T (MAX) accuracy 1% FS

Applications and benefits:

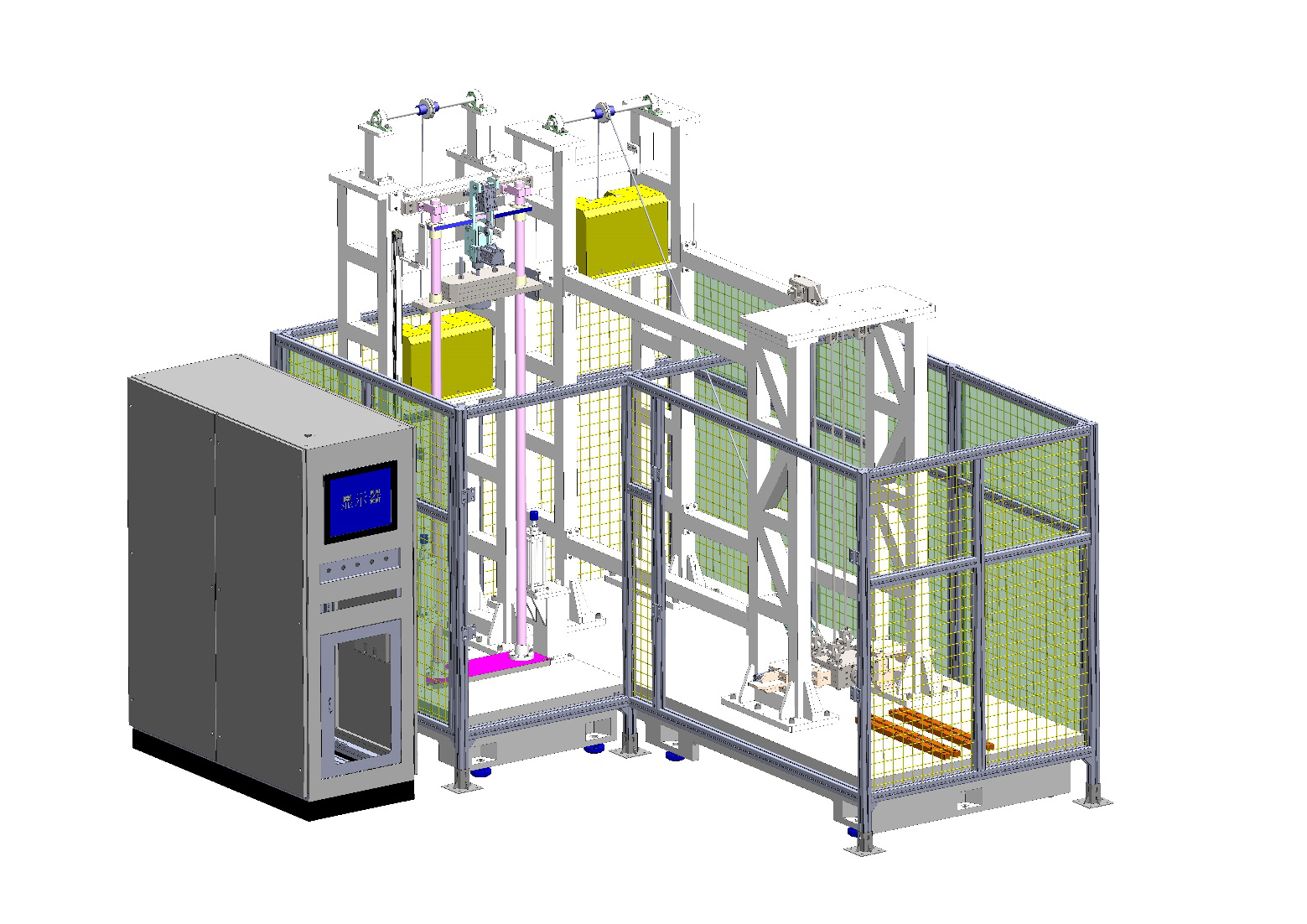

● Suitable for two impact tests of steering gear drop hammer and pendulum

● The device uses impact force acquisition technology to collect the instantaneous impact force of the impact process and calculate the maximum impact pressure.

● Automatic detection of the lifting angle of the pendulum and the lifting height of the drop hammer

● Automatic control of pendulum and drop hammer impact process without manual intervention

● Safety protection during equipment experiment, protective fence around the equipment to protect personal safety

● Industrial computer is used to realize the automatic control of the test process and the automatic display, printing and test curve display of the test results, and can be evaluated according to the given indicators and automatically generate test reports.

● The fixture adopts the pallet to meet the test fixture of the same machine.